-

February 26, 2020 by Total Fire and Safety

Restaurant fires destroy more than property. Restaurants hold priceless memories of celebrations and firsts, meetings with important people, backgrounds for special announcements or the reliable spot to pick up favorite weekday takeout meals. With a fire, they all go up in smoke—literally. Restaurant fires can be devastating, not only to the owners and patrons, but to the employees as well.

Nearly 8,000 restaurant fires occur each year resulting in $165 million in property damage. According to the NFPA, cooking equipment was the leading cause of restaurant fires (61%), electrical equipment (9%), heating equipment (9%), and smoking materials (7%). What’s the best way to protect your restaurant from a fire? Understand the dangers and prevention measures you can take to skirt disaster in your dining or takeout establishment.

DANGER:

Exhaust Systems and Ductwork

The vents and fans behind ovens and stoves accumulate a buildup of grease. Since the vents and fans extract flammable vapors, a spark can light grease buildup. Oven hoods above stoves, can also harbor flammable vapors from contaminated cooking air. This can feed through the exhaust system and cause a fire hazard. Also included in these systems are grease traps. Most commercial kitchens are required to maintain a grease trap preventing oils and fats from clogging sewers.

PREVENTION

- Clean all areas daily

- Twice a year, have a thorough hood cleaning by professionals

- Clean grease traps monthly, quarterly, or yearly as mandated by the NFPA

DANGER:

Gas Leaks

Gas leaks are the most catastrophic cause of restaurant fires because they cause an explosion. Gas leaks occur when faulty equipment is unable to support the flow of gas and leaks flammable gas in the air. A simple electrical device can ignite the gas and lead to an explosion.

PREVENTION

- Be alert and detect the signs of a gas leak (gas smell, orange/yellow flames, extinguished pilot lights)

- Perform equipment inspections daily and replacement of worn out equipment

DANGER:

Electrical Problems

Heat from unsafe or poor wiring in switches, sockets, or plugs can spark flammable or combustible materials. Overloading outlets, outdated wiring, and overpowering kitchen equipment can lead to a fire or even explosion.

PREVENTION

- Use only commercial equipment that is up-to-code

- Update wiring that can handle a busy kitchen

In the unfortunate event a restaurant fire occurs, a fire suppression system is your best protection. A restaurant fire suppression system is designed to provide fire protection for restaurant cooking appliances, exhaust hoods, and ducts. A fire suppression system detects fires through heat sensors, often before the kitchen staff does. When automatically discharged, the fire can be suppressed at its earliest stages. The result is minimal damage to the kitchen and minimal equipment down time.

Keep your restaurant kitchen safe from fires by properly installing and maintaining a working fire suppression system and empowering employees with fire safety and response training. It can mean the difference between a localized fire and a major blaze.

If you’re ready to safeguard your kitchen from a restaurant fire, Total Fire and Safety can test, service, and install fire suppression systems. TFS also provides first aid and fire extinguisher training on-site. Give us a call today and let our professionals provide “total” assurance your restaurant is protected from fire. Call us at 630.960.5060.

Category: Business Safety, Fire Equipment Inspections, Suppression system, Total Fire and Safety Tags: commercial fire protection, commercial fire safety, commercial fire suppression, fire and safety equipment, fire and safety needs, fire supression system, Total Fire & Safety | Comments Off on The Dangers and Prevention of Restaurant Fires

-

January 27, 2020 by Total Fire and Safety

How important is the fire code for animal shelters? Deadly fires at kennels and animal shelters are not uncommon across the U.S. In the past year, over 100 dogs have died in kennel fires, including here near Chicago.

On the night of January 14, 2019, a West Chicago animal kennel went up in flames. Thirty-one dogs perished in the fire. The exact cause of the fire is unknown, but investigators determined no staff was present at the time and no working fire sprinklers were on property. The kennel did have fire detectors, but no one was around to hear them.

The tragedy prompted lawmakers to come up with legislation to ensure such an event never happens again. The new law, signed in August, went into effect January 1. The legislation requires kennels to be staffed 24/7 or have sprinkler systems or alarms that alert local fire departments.

When it comes to arming animal shelters with lifesaving equipment, Total Fire and Safety can help with the installation of …..

Wireless Fire Alarms

- Preferred by fire departments, they are more reliable than land-based systems for their quick and accurate response.

- They can save phone line costs.

- They reduce false alarms to fire departments

- Minimal and guaranteed wireless radio alarm monitoring fees

Fire Sprinkler Systems

- A working fire sprinkler is 96% effective in containing a fire.

- Monthly, quarterly, and annual inspections are necessary to ensure safety and keep your building fire code compliant.

- TFS uses the most up-to-date technology and thorough process to prevent sprinkler failure.

Working fire extinguishers can keep a small fire from getting out of control when someone is in the facility. Every business needs working fire extinguishers at the ready, and be trained to use them.

- A fire extinguisher is your first line of defense, 24/7.

- 30% of fire extinguishers are not in working order. We complete a 12-point inspection to make sure they are fire ready.

- On-site training is provided to guarantee proper employee usage.

All it takes is basic fire protection to save animal and human lives.

Illinois’ new fire code will help protect our furry friends from another senseless tragedy and prevent irreparable damage to lives, structures, and pocketbooks. Total Fire and Safety can equip your facility with the latest fire protection and help maintain the equipment installed. Give us a call today at (630) 960-5060.

Category: Business Safety, Fire Alarm Monitoring, Fire Extinguishers, Fire Extinguishers, Fire News, Fire Safety, Sprinkler Systems, Total Fire and Safety Tags: commercial fire safety, commercialfiresprinkler, employee training, fire and safety equipment, fire and safety solutions, fire safety in the news, Firesprinkler, Total Fire and Safety, wireless fire alarm monitoring, wireless fire alarms, wireless fire alarms for business | Comments Off on A New Fire Code for Animal Shelters in Illinois!

-

December 23, 2019 by Total Fire and Safety

We wish you the warmth and cheer of the season!

Thank you for your continued support throughout the year.

From all of us at Total Fire & Safety

Twelve Days of Fire Safety

On the first day of safety, Total Fire gave to me…

A safe and code compliant facility!

On the second day of safety, Total Fire gave to me…

Two emergency plans

and a safe and code compliant facility!

On the third day of safety, Total Fire gave to me…

Three eyewash stations

Two emergency plans

and a safe and code compliant facility!

On the fourth day of safety, Total Fire gave to me..

Four first aid kits

Three eyewash stations

Two emergency plans

and a safe and code compliant facility!

On the fifth day of safety, Total Fire gave to me…

FIVE WIRELESS ALARMS

Four first aid kits

Three eyewash stations

Two emergency plans

and a safe and code compliant facility!

On the sixth day of safety, Total Fire gave to me…

Six extinguishers inspected

FIVE WIRELESS ALARMS

Four first aid kits

Three eyewash stations

Two emergency plans

and a safe and code compliant facility!

On the seventh day of safety, Total Fire gave to me…

Seven exit signs Six extinguishers inspected

FIVE WIRELESS ALARMS

Four first aid kits

Three eyewash stations

Two emergency plans

and a safe and code compliant facility!

On the eight day of safety, Total Fire gave to me…

Eight backflow inspections

Seven exit signs

Six extinguishers inspected

FIVE WIRELESS ALARMS

Four first aid kits

Three eyewash stations

Two emergency plans

and a safe and code compliant facility!

On the ninth day of safety, Total Fire gave to me…

Nine sprinkler systems

Eight backflow inspections

Seven exit signs

Six extinguishers inspected

FIVE WIRELESS ALARMS

Four first aid kits

Three eyewash stations

Two emergency plans

and a safe and code compliant facility!

On the tenth day of safety, Total Fire gave to me…

Ten safety trainings

Nine sprinkler systems

Eight backflow inspections

Seven exit signs

Six extinguishers inspected

FIVE WIRELESS ALARMS

Four first aid kits

Three eyewash stations

Two emergency plans

and a safe and code compliant facility!

On the eleventh day of safety, Total Fire gave to me…

Eleven fire pumps serviced

Ten safety trainings

Nine sprinkler systems

Eight backflow inspections

Seven exit signs

Six extinguishers inspected

FIVE WIRELESS ALARMS

Four first aid kits

Three eyewash stations

Two emergency plans

and a safe and code compliant facility!

On the twelfth day of safety, Total Fire gave to me…

Twelve new extinguishers

Eleven fire pumps serviced

Ten safety trainings

Nine sprinkler systems

Eight backflow inspections

Seven exit signs

Six extinguishers inspected

FIVE WIRELESS ALARMS

Four first aid kits

Three eyewash stations

Two emergency plans

and a safe and code compliant facility!

Category: Fire Alarm Monitoring, Fire Equipment Inspections, Fire exits, Fire Extinguishers, Fire News, Fire Safety, Sprinkler Systems, Total Fire and Safety, Uncategorized Tags: commercial fire safety, fire and safety equipment, fire and safety solutions, Fire Extinguisher, fire safety, Total Fire & Safety, wireless fire alarms | Comments Off on Happy Holidays from Total Fire & Safety

-

November 12, 2019 by Total Fire and Safety

Does your organization have a first aid kit hanging on the wall? It sits there silently like a dutiful soldier, ready and waiting for any emergency. But with winter on its way, you may be surprised at how often that first aid kit can be called into service during the coldest months of the year.

Winter weather can easily compromise employee safety, whether the workplace is outdoors or in an office. It is important to keep first aid kits well stocked with winter safety essentials. Before you start planning your holiday office party, let’s look at your first aid kit and what we can do to “winterize” it.

OSHA has established a list of required first aid supplies for the workplace. Depending on the business and specifics of the environment, there are different first aid requirements. Employers are responsible for keeping the first aid kit stocked and up to date with the necessary supplies needed. They include:

- Band-aids, Elastic Bandages/Adhesive Tape, Sterile Gauze Pads/Rolls and Large Pressure Bandages in different shapes and sizes of bandages for possible falls, cuts, and scrapes. The opening of cracked, chapped winter skin can precipitate the need for a band-aid or a fall on the ice can merit more serious first aid treatment.

- Non-Latex Gloves, Antiseptic wipes, Peroxide and Alcohol and Triple Antibiotic Ointment will help keep those helping tend a wound safe, and also help the wound heal more quickly. Protect skin from contamination.

- Eye Pads and Eye Wash can help tend weather-related discomforts on the way into work.

- Tongue Depressors can be used to check throat irritations during winter flu season or be used as splints for possible weather-related injuries.

- CPR Shields can protect users from bodily fluids when CPR is essential. In winter, shoveling and overexertion in the cold can lead to cardiac arrest and the need for onsite CPR. Total Fire & Safety can help with employee training in this area.

- Triangular Bandages can be onsite in the event of the need for a sling or tourniquet. Falls on ice or minor accidents may require such dressings.

- Cold Packs: Instant cold packs help with sprains, fractures, burns, etc.… common injuries associated with falls, accidents, or overheating.

- Thermometer: Determines body temperatures. The flu and other winter maladies can be contagious! Detecting an above normal temperature in an employee can prevent an outbreak that can take down a workplace.

- Aspirin, Tylenol, or Motrin can help alleviate the symptoms of a cold.

- Penlight can be used to look in ears and throats for maladies, or even pupils for possible concussion victims.

- Antihistamine Tablets and Hydrocortisone to quell the allergies and dermatitis from the dry air, increased dust, and lack of fresh air during the winter months.

- Blankets to use in emergencies, such as frostbite, hypothermia, etc.

For any company, the first aid kit can be your first offense against the common winter injuries that employees can suffer en route or while at work:

Sprains and Broken Bones

Ice covered roadways, sidewalks, parking lots, and driveways put you at risk for a nasty fall which can result in a sprain or broken bone. If the injury is minor and does not require an immediate doctor’s care, delve into your first aid kit and treat the injury with RICE:

1. Rest the injured limb with crutches, a sling, or splint, or anything you can to keep from putting stress on it.

2. Ice the injured limb. Apply a cold pack to the area to prevent swelling.

3. Compress the injury by wrapping a bandage around it or use a sleeve.

4. Elevate the injured limb above the heart to reduce swelling.

In addition, offer the victim Tylenol, Aspirin, or Motrin for pain and swelling.

Frostbite

Frostbite occurs when skin cells and tissues freeze, damaging the skin walls. Most often it happens to fingers, toes, noses, cheeks, chin, ears, and the areas with most exposed skin. If frost bite should happen, remove the victim from the cold. Warm their hands by tucking them under the armpits. Cover the nose, ears, and face and remove any wet clothing. Once in warm shelter, place frostbitten areas under warm, not hot, water. Avoid direct heat. Treat pain with Tylenol, Aspirin, or Motrin from your first aid kit. If blisters or numbness continues, seek medical attention.

Hypothermia

Hypothermia happens when the body’s internal temperature drops below 95 degrees. Call 911 immediately. A person’s breath can become shallow or they can stop breathing all together. If this happens, CPR must be administered using a CPR shield from your first aid kit. If CPR is not necessary, get the person away from the cold and wrap them in a blanket, also in your first aid kit. Apply a warm compress to the chest, neck, groin, and head.

Winter weather can be dangerous and serious injuries can occur, beyond what a first aid kit is capable to handle. Assess the situation and call 911, if needed, first.

Total Fire and Safety can help you keep your first aid kits stocked appropriately and provide on-site first aid training for employees. Be prepared for winter! Give us a call today! (630)960-5060.

Category: Business Safety Tags: commercial fire protection, commercial fire safety, fire and safety solutions, first aid, first aid supplies, Total Fire & Safety | Comments Off on Fighting Winter Ills with the Company First Aid Kit

-

October 2, 2019 by Total Fire and Safety

Fire prevention week has been designated as October 6-12, 2019 by the National Fire Protection Association (NFPA). Fire prevention week has a long history, dating back to 1925, when President Calvin Coolidge proclaimed fire prevention week as a national observance. Now, it has become the longest running health observance in the country.

At Total Fire & Safety, we use this time to reiterate to our clients how important it is to stay compliant with NFPA codes and keep everyone within their buildings, warehouses and commercial spaces supplied with fire extinguishers, sprinklers, and suppression systems that are ready to go when fire strikes.

The theme of this year’s campaign is “Plan and Practice Your Escape.” So how can a business observe National Fire Prevention Week? Here’s a few ideas.

- Share safety information from the NFPA with your employees. Not only will it help them at work, but at home too!

- If you do not do so regularly, heed the theme of the program and “plan and practice your escape.” Every employee should be mindful of their best options in the event of an emergency.

- Call your fire protection service for an inspection of your equipment and make sure all your extinguishers, alarms, sprinkler systems, etc. are in working order.

- Consider a training class for fire extinguisher operation, first aid, or CPR.

Around the Total Fire & Safety service area, the observance is being commemorated with lots of events at community fire stations. For more information, see the website for each individual fire department.

Friday, Oct. 4

Saturday, Oct. 5

- Tinley Park Fire Department: 17355 68th Court, Tinley Park, 9 a.m. – 1 p.m. Open House

- Schaumburg Fire Department: 950 W. Schaumburg Road, Schaumburg, 11 a.m. – 2p.m. Public Safety Open House

- Clarendon Hills Fire Department: 316 Park Ave., Clarendon Hills, 11 a.m. – 2 p.m. Open House

- Minooka Fire Department: 7901 E. Minooka Road, Minooka, 11 a.m. – 2 p.m. Open House

- Hazel Crest Fire Department: 2903 W. 175th St., Hazel Crest, 9 a.m. – 12 p.m. Open House

- Frankfort Fire District: 20101 La Grange Road (Event address), Frankfort, IL 60423, 9:30 a.m. – 12:30 p.m. Gas Safety Event

- Palatine Fire Department: 39 E Colfax Street, Palatine, IL 60067, 10 a.m. – 2 p.m. Open House

- Darien-Woodridge Fire District: 7550 Lyman Ave., Darien, IL 60561, 10 a.m. – 1 p.m. Open House

- Oswego Fire Protection District: 3511 Woolley Road, Oswego, IL 60543, 11 a.m. – 3 p.m. Open House

- Calumet City Fire Department: 24 State Street, Calumet City, IL 60409, noon

Sunday, Oct. 6

- Belvidere Fire Department: 123 S. State Street, Belvidere, IL 61008, 1 – 4 p.m. Open House

- Mokena Fire Protection District: 19853 S. Wolf Road, Mokena, IL 60448, 7:30 a.m. – noon Open House

- Lake Zurich Fire Department: 321 South Buesching Road, Lake Zurich, IL 60047, 11 a.m. – 2 p.m. Open House

- Batavia Fire Department: 1400 Main St, Batavia, IL 60150, 11 a.m. – 3 p.m.

- McHenry Township Fire Protection District: 3610 W. Elm Street, District Administration Office, McHenry, IL 60050, 11 a.m. – 1 p.m.

- Naplate Fire Department: 2000 W Ottawa Ave, Naplate, IL 61350, 12 – 3 p.m.

- Manteno Community Fire Protection District, 13 S WALNUT ST, MANTENO, IL 60950, 12 – 3 p.m.

Monday, Oct. 7

- Western Springs Fire Dept: 4353 Wolf Road, Western Springs, IL 60558, 6 – 8:30 p.m. Open House

Wednesday, Oct. 9

- Lombard Fire Department: 50 E St Charles Road, Lombard, IL 60148, 6 – 8 p.m. Open House

- Downers Grove Fire Department: 6701 Main Street, Downers Grove, IL 60516, 6:30 – 8:30 p.m. Open House

Thursday, Oct. 10

Friday, Oct. 11

- South Chicago Heights Fire Department: 185 W Sauk Trail, South Chicago Heights, IL 60411, 5:30 – 7:30 p.m. Open House

Saturday, Oct. 12

- Northbrook Fire Department: 1840 Shermer Road, Northbrook, IL 60062, 9 a.m. – 12 p.m. Open House

- Crystal Lake Fire Rescue: 100 W Woodstock St, Crystal Lake, IL 60014, 9 a.m. – 12 p.m. Open House

- Prospect Heights: 10 E. Camp McDonald Rd, Prospect Heights, IL 60031, 9 a.m. Open House

- La Grange Park Fire Department: 447 N. Catherine Ave., La Grange Park, IL 60526, 10 a.m. – 1 p.m. Open House

- Elgin Fire Department: 650 Big Timber Road, Elgin, IL 60123, 10 a.m. – 3 p.m. Open House

- City of Rockford: 204 S. First St., Rockford, IL 61104, 10 a.m. – 1 p.m.

- Homewood Fire Department: 17950 Dixie Highway, HOMEWOOD, IL 60430, 11 a.m. to 2 p.m.

- Plainfield Fire Protection District: 23748 W. 135th Street, Plainfield, IL 60544, 11 a.m. – 2 p.m. Open House

- Westmont Fire Department: 6015 S. Cass Ave., Westmont, IL 60559, 11 a.m. – 3 p.m. Open House

- Alsip Fire Department: 11946 S. Laramie, Alsip, IL 60803, 1 – 3:30 p.m. Open House

- Calumet City Fire Department, Station 2: 1270 Pulaski Rd, Calumet City, 12 – 3 p.m. Open House

Sunday, Oct. 13

- North Palos Fire Protection District: 10629 S Roberts Rd, Palos Hills, IL 60465, 7 a.m. – 12 p.m.

- Byron Fire Department: 123 S. Franklin St., Byron, IL 61010, 11 a.m. – 3 p.m. Open House

- Elmhurst Fire Department: 601 S York, Elmhurst, IL 60126, 12 – 4 p.m. Open House

Wednesday, Oct. 23

- Chicago Ridge Fire Department: 10063 Virginia, Chicago Ridge, IL 60415, 6 – 9 p.m.

Fire protection and preparation is not just a week-long observance but a 365 day a year, 24/7 job. At Total Fire & Safety, we have everything you need to keep your employees and tenants protected. If we can ever assist your business with NFPA compliance for your commercial fire protection, contact us at 630-960-5060.

Category: Business Safety, Fire Equipment Inspections, Fire exits, Fire News, Fire Safety, Health and Safety, LED Lighting, NFPA Compliance, Total Fire and Safety Tags: commercial fire safety, emergency exit lights, fire and safety equipment, fire and safety needs, fire and safety solutions, fire safety in the news, lifesafety | Comments Off on 2019 Fire Prevention Week is for Businesses Too!

-

September 25, 2019 by Total Fire and Safety

If you have ever visited a historic building, what do you notice? Old documents, precious artwork, impeccable craftmanship, and… fire protection equipment? Hopefully your answer to the latter is no. Ideally, historic properties should still maintain the look and feel of an era gone by, but how do you do it and still install and maintain fire equipment that’s up to code?

Everyday commercial buildings are damaged by fires, causing a huge loss for any business. However, these damages can be repaired, sometimes improving the building from its previous structure. This is not the case for historic properties. The true extent of the loss is more significant than the cost of simply restoring the building. Any artifacts, documents, etc. that are lost represent a priceless piece of our heritage.

For the fire safety expert, the challenge of fire protection in a historic building presents three distinctive challenges:

Preserving the Historic Character

In order to protect historic buildings, sometimes structural engineers, preservation specialists and the building managers must get involved in addition to the fire protection experts (TFS). Together they design a solution that meets the needs of NFPA compliance without ruining the historic character of a building. For example, a historic door cannot be replaced with a fire-proof door, however installing sprinklers on either side of the door may be the answer.

Fire safety is prioritized even with our most beloved historic institutions. For example, currently there is a major renovation going on at Mount Vernon, the home of our first president, George Washington. Part of this extensive construction is major improvements to the fire suppression system. When all is said and done, fire safety for Mount Vernon and its visitors will be vastly improved for generations to come.

Total Fire & Safety’s client roster includes many historic buildings, especially in the Village of Downers Grove. We are proud to be able to keep visitors safe while maintaining the distinctive character of each building.

Staying Out of Sight

Ideally, fire protection systems must sufficiently protect a building but remain aesthetically pleasing. One common cause of concern is the fire sprinkler system. Not only do fire sprinklers damage a building’s contents, but they can deface the historic structure. The answer lies in coming up with creative solutions for fire sprinklers:

1. Use copper tubing vs. black or steel pipe to blend in with the building’s architecture.

2. Faux materials can be used that resemble the buildings time period to conceal fire sprinkler pipes.

3. Install painted fire sprinkler heads to match the area.

Another form of hidden fire protection commonly used in historic buildings is wireless fire alarms. Wireless alarms are an ideal, minimally invasive solution when needing to preserve the look and feel of a building. Other advantages to wireless fire alarms include:

- Wireless alarm monitoring provides faster response

- No cables are required for installation

- They eliminate false alarms, which can be costly for non-profit buildings

Updating Outdated Utilities

Many historic facilities have poor water pressure. This renders a fire sprinkler upgrade useless unless an underground line, additional line, or fire pump is installed. Total Fire & Safety can be helpful in making the right decision for any historic property.

Regardless of the fire protection systems installed, working to minimize the ignition of a fire should be a priority. Scheduling fire safety inspections annually is important to maintain a safe environment for the building and its occupants. Total Fire and Safety works not only to uphold the integrity of an historic building, but also provides the best fire protection equipment around. Give us a call today! 630-960-5060

Category: Business Safety, Fire Equipment Inspections, Fire exits, Sprinkler Systems, Total Fire and Safety Tags: commercial fire protection, commercial fire safety, commercialfiresprinkler, fire and safety equipment, fire and safety needs, fire and safety solutions, Firesprinkler, firesprinklerinspections, Total Fire and Safety, wireless fire alarm monitoring, wireless fire alarms, wireless fire alarms for business | Comments Off on Preserving Fire Safety in Historic Buildings

-

July 23, 2019 by Total Fire and Safety

When people think of careers in fire safety in Illinois, they usually think of firefighters. But what about the folks who prevent the fires in the first place? These dedicated professionals work in the area of commercial fire safety. They help commercial buildings and residential dwellings stay up to code with the fire safety equipment, and thus, can save lives indirectly by keeping people safe and prepared for fire emergencies.

Providing fire safety to any business, at any level, starts with teamwork. If one aspect of fire safety fails (sprinkler, extinguisher, or alarm), it can make the difference between life and death. All the fire safety components work within a life safety ecosystem, which includes government code compliance, a skilled workforce, and an investment in safety equipment, installation, and training. As part of a commercial fire safety team such as Total Fire and Safety, you are part of a life-saving mission. We provide customers their first offense in putting out a fire on their premises.

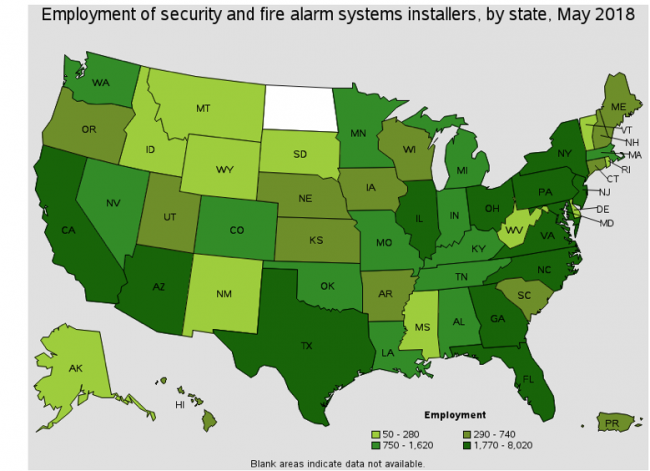

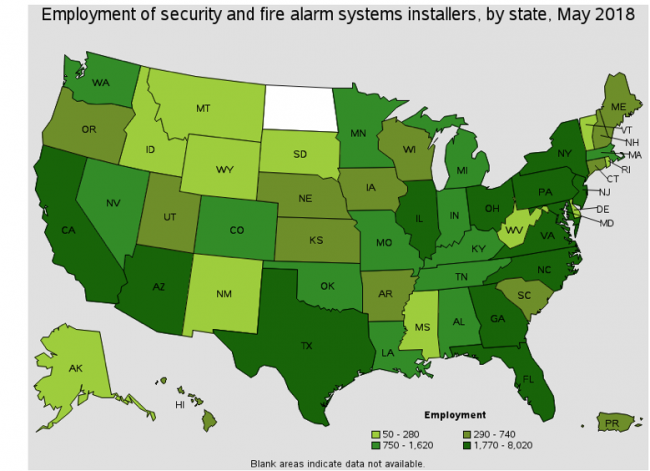

According to the Bureau of Labor Statistics and their Occupational Outlook Handbook, the projected employment change for security and fire alarm system installers is expected to grow 14 percent, which is faster than the average career. They are expecting growth of 10,400 new jobs between 2016-2020. Currently, Illinois, the home state of Total Fire & Safety, is among the states in the nation that employs the most installers in this field. (see chart below).

Chart reprinted from Bureau of Labor Statistics, Occupational Employment and Wages, May 2018, 49-2098 Security and Fire Alarm Systems Installers

Many of the careers in fire safety require a high school diploma or equivalent but mainly, on-the-job training. At Total Fire & Safety, we have a vigorous employee training program that prepares our people for many of the jobs that are so needed in the industry, such as customer service, sales representatives, dispatchers, fire alarm service technicians, fire extinguisher technicians, fire sprinkler service technicians, etc. We even have an on-site training facility (pictured below) where we regularly host classes and training modules for TFS employees.

You’ve heard the phrase teamwork makes the dream work, right? At Total Fire and Safety we are always looking for dedicated professionals to join our commercial fire safety team, which has that has provided fire safety for over 30 years. If you are looking for employment or are ready for a career change, join Total Fire and Safety and see how working as a team can save lives.

To learn more about the opportunities available and experience needed at Total Fire and Safety, visit our employment page or search us on Indeed.

Category: Business Safety, Fire Safety, Total Fire and Safety Tags: commercial fire protection, commercial fire safety, employee training, fire and safety equipment, fire safety, fire safety training, Fireextinguishertraining, firesafetytraining, Total Fire and Safety, training | Comments Off on Find Your Career in Illinois Commercial Fire Safety

-

June 19, 2019 by Total Fire and Safety

According to legend, the cause of the greatest fire in Chicago was a cow kicking over a lantern in a barn. In 1871, the entire city of Chicago was engulfed in flames. The fire lasted two days, left 300 people dead and over $200 million in damage. The event changed Chicago. Stricter fire codes were implemented, structures were built with different materials, and fire departments were equipped with better equipment and advanced training methods.

Today, fires in Chicago rarely go unexplained due to investigative divisions within the fire departments. The investigative teams are well trained in how to identify common causes of fires in Chicago. The most common causes of fires in Chicago vary by type.

Common Causes of Residential Fires

- Overusing extension cords

- Overusing Christmas lights/stringing them together under furniture

- Smoking materials (cigarettes, cigars, etc.…)

- Heating or electrical malfunction

- Cooking or kitchen fires

Common Causes of Industrial Fires

- Combustible dust

- Hot work

- Flammable gas or liquid

- Equipment and machinery fires

- Electrical hazard fires

How Fires are Investigated

Whether it is a residential fire or industrial fire, criminal or accidental, fires in Chicago and around the country all have a determining factor. The responsibility for finding the determining factor is up to the fire department. From a public standpoint, finding a cause seems impossible. How do they do it?

Upon arriving at the scene, firefighters note the color of the flames, the amount of smoke, the rate at which the fire spreads, and the sound it makes. These are all clues as to what is burning and how it is burning. It is incumbent of the firefighters to protect the evidence at the scene by:

- Limiting excessive fire suppression

- Preventing needless destruction to a property

- Using markers or cones to identify evidence

- Writing notes or making voice recordings of observations

- Covering areas that contain evidence

- Preserve delicate evidence like shoe or tire tracks

Once the fire is extinguished, the fire investigators dig through the ashes. They take photographs prior to and during the investigation for documentation. The objective of investigators is to locate the point of origin. This is achieved through the char patterns, direction of melt, and heat shadows. The burn patterns are often “V” shaped like an inverted cone. The fire burns upward, in a V-shaped pattern away from point of origin. The location is usually the most damaged by the fire. Although most of the determination of origin is science-based, there is a little bit of guessing and witness accounts. Fires in Chicago are likely to have one of four reasons:

- Electrical issues

- Natural acts

- Open flames

- Human action

Fires in Chicago have decreased over the years with an average of eight fire per day. Fortunately, fatal fires are rare, but even one is too many. It’s important for residents and businesses to practice fire safety. Is your business well equipped against fires? Total Fire and Safety can help safeguard your building and those occupying it with fire alarms, fire extinguishers, first aid kits, emergency lights and more. We’ll inspect your property to ensure it is up to code and even provide training classes for employees so they know how to use the equipment in an emergency. Give TFS a call today at 630-960-5060.

Category: Business Safety, Fire Extinguishers, Fire News, Fire Safety Tags: commercial fire protection, commercial fire safety, fire and safety solutions, Fire Extinguisher, fireextinguisher, firesafetytraining | Comments Off on In the Aftermath: Finding the Causes of Fires in Chicago

-

April 24, 2019 by Total Fire and Safety

According to the National Fire Protection Agency (NFPA), between 2011 and 2015, there was an estimated 37,910 fires at industrial properties each year. These industrial fires resulted in 16 civilian deaths, 273 civilian injuries, and $1.2 billion in property damage.

Industrial fires are serious, but there are several things you can do at your plant or factory to minimize the possibility of an industrial fire. First, it’s important to know how they usually start.

The five most common causes of industrial fires are…

1. Combustible Dust Fires

A combustible dust is any dust or fine material that has the potential to catch fire and explode when it is mixed in the air. Many times, materials that are normally considered non-flammable can act as a combustible when fine particles are mixed with air in a particular concentration. Combustible dust happens in two waves. A primary explosion causes particles to become airborne, and then the dust cloud can ignite and cause a secondary explosion, much more severe than the first. Combustible dust can bring down entire facilities.

How do I Prevent Combustible Dust Fires?

- Implement a hazardous dust inspection, testing, housekeeping, and control program.

- Regularly inspect for dust residues in open and hidden areas.

- Use proper dust collection systems.

- If ignition sources are present, use cleaning methods that do not generate dust clouds.

- Control smoking, open flames, and sparks (mechanical and friction).

2. Hot Work Fires

Hot work is any activity that involves open flames or generates sparks or heat. This includes welding, heat treating, grinding, thawing pipes, torch cutting, brazing, soldering, etc. Hot work becomes a fire hazard when sparks and molten material travel…often as far as 35 feet, sometimes igniting combustible dust in other areas.

How do I Prevent Hot Work Fires?

- Train personnel on the hazards associated with hot work and make sure they are using proper safety equipment.

- Clear area of flammable materials including dust, gases, and liquids.

- Make sure a safety professional is on site to provide supervision of the work.

- Avoid hot work if possible.

3. Flammable Liquid and Gas Fires

These are most common in chemical plants. Flammable liquids and gases can ignite off sparks from the previous hazards or add fuel to an already burning fire.

How Do I Prevent A Flammable Gas Fire?

- Know the hazards of each flammable liquid and gas on-site. Read and follow the safety information for storage and follow the material safety data sheet included with the product.

- Properly store hazardous materials according to OSHA.

- Keep ignition sources away from flammable gases and liquids.

- Provide personal protective equipment, like gloves, bodysuits, vests, goggles, shoes etc.

4. Equipment and Machinery Fires

Equipment not properly installed, maintained, or operated correctly is a major cause of industrial fires. This is especially true for equipment associated with hot work and heating. Even machinery not seen as a fire hazard can become a risk with lack of proper maintenance.

How Do I Prevent Equipment and Machinery Fires?

- Training can help employers and employees identify possible risks and what to do if they find one.

- Keep the machines, equipment, and areas surrounding them, clean.

- Prevent machine overheating by following the manufacturer’s guidelines for recommended maintenance procedures.

5. Electrical Hazard Fires

Electrical fires are most common in manufacturing plants and include wiring that is exposed or not up to code, overloaded outlets, extension cords, overloaded circuits, static discharge, etc. A spark from electrical hazards can cause ignition of combustible dust and flammable liquids and gases.

How Do I Prevent Electrical Hazard Fires?

- Don’t overload electrical equipment or circuits.

- Unplug temporary equipment not in use.

- Avoid using extension cords.

- Use antistatic equipment as advised by OSHA and NFPA.

- Follow a regular cleaning schedule to ensure combustible dust and other hazardous materials are removed from areas that house equipment and machinery.

It can seem overwhelming to have to safeguard your facility against industrial fire hazards, but the pros at Total Fire and Safety can help you identify and prevent risks throughout your facility. They also provide fire safety training to educate employees on proper fire safety equipment operation and life safety procedures.

To take the first step in keeping industrial fires at bay at your facility, call Total Fire and Safety at 630-960-5060 or reach us at our 24/7 emergency line, 630-546-8909.

Category: Business Safety, Fire Safety, NFPA Compliance Tags: commercial fire protection, commercial fire safety, fire and safety solutions, fire safety training, Industrial Fire Prevention, Industrial Fire Safety, Total Fire & Safety | Comments Off on The Best Way to Prevent Industrial Fires

-

March 22, 2019 by Total Fire and Safety

In a commercial building, a fire sprinkler system is one of the most effective ways to control and extinguish fires. A well maintained fire sprinkler system can mean the difference between minor damage and total destruction.

A fire sprinkler system is a group of pipes and sprinkler heads located on ceilings or overhead. They slow the spread of fire or extinguish fire by releasing a spray of water. They are designed to cover as much area as possible to provide widespread coverage.

Most fire sprinklers are heat activated. When heat is detected, water is released and the fire alarm will likely be activated. Obviously, we need fire sprinklers to be as reliable as possible. So when and why do they fail?

The NFPA reports that there are an average of 660 reported sprinkler failures a year. However, with a proper working fire sprinkler 96% of the time they are effective in controlling most fires. The most common causes of sprinkler failures are:

- System shut-off

- Manual intervention

- Damaged components of fire sprinklers

- Lack of maintenance

- Inappropriate design of the fire sprinkler systems

Fortunately, most of these problems can be alleviated with proper, regular inspection of your fire sprinkler system by a trained professional. The NFPA suggests different intervals per year in order to ensure effectiveness.

Monthly inspection should ensure that

- Valves are accessible, labeled properly and are not leaking

- Wet gauges should be in good condition with proper water pressure detected

- Dry gauges should have normal water pressure with the quick opening device showing the same pressure as the dry pipe valve

Quarterly inspection should:

- Check for physical damage to the supervisory alarm and water flow alarm

- Dry test the system to check for valve issues

- Check that all fire department connections are accessible

- Check for leaks around the fire department connections

- Inspect pressure reducing valves (free of leaks, open position, maintaining downstream pressure)

Annual inspection should include all of the above, plus professional inspection by a certified professional for code compliance and tagging.

Well-maintained fire sprinkler systems are paramount to your building safety and occupants. The professional at Total Fire and Safety is dedicated to keeping you safe and in code compliance. Give us a call today to schedule an inspection at 630-960-5060.

Category: Business Safety, Fire Safety, Sprinkler Systems, Total Fire and Safety Tags: commercial fire safety, commercialfiresprinkler, fire safety, Firesprinkler, firesprinklerinspections, sprinkler, sprinklerinspections | Comments Off on Will your fire sprinkler system work when the heat is on?

|

|

|

|

|

|

|

Facebook

Facebook

Instagram

Instagram

LinkedIn

LinkedIn